Powering the future of green hydrogen

Producing cost-effective and reliable green hydrogen is achieved by customising the Power Supply Unit to various plant-specific requirements.

Designed specifically for green hydrogen plants, our Power Supply Units (PSUs) are customised to meet electrolyzer, grid, and plant requirements.

We leverage proven products and expertise from the wind industry to help electrolyzer OEMs and project developers reduce costs and complexity, delivering customisable Power Supply Units with exceptional efficiency and reliability.

Built for cost-effective customisation, our Power Supply Units ensure a precise fit with your plant’s technical and operational requirements, contributing to a lower Levelised Cost of Hydrogen (LCOH).

MAXIMUM EFFICIENCY & RELIABILITY

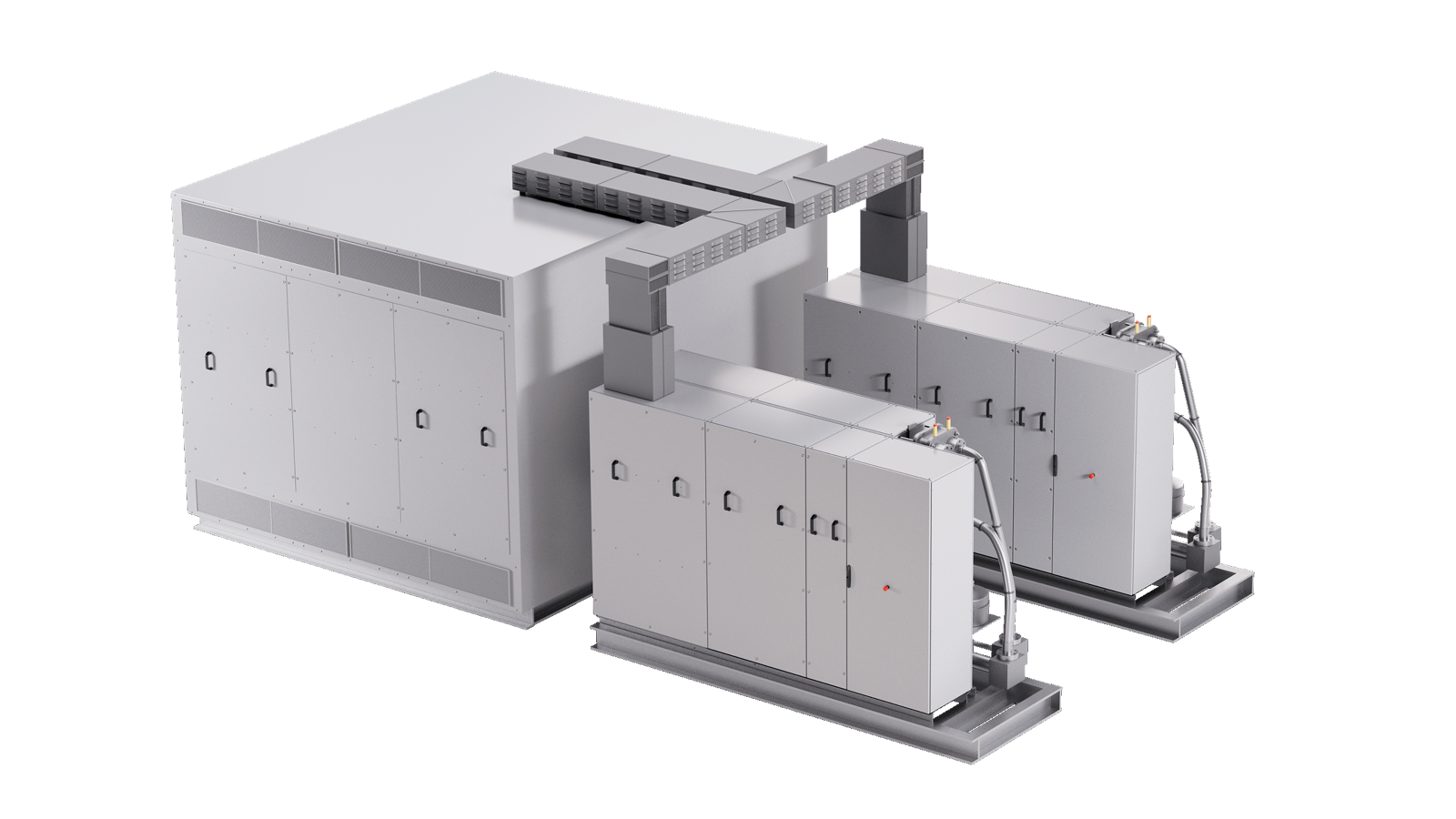

End-to-end Power Supply Units

Customisation options include transformer type, AC connection, rectifier variant, control system, cooling solution, and configurations for indoor or outdoor installation.

1

1MV Switchgear

Optional configuration

AC Connection

Busbar or cable configurations are available

Outdoor Protection

Optional: Enhanced IP rating and corrosion protection for outdoor use

DC Outlet

Available with top or bottom terminals for connection via busbar or cables

Cooling System

Optional: Liquid/liquid or liquid/air

Step-Down Transformer

Optional: Enclosure available

High DC Voltage Rectifier

Various PWM controlled AC/DC rectifier configurations available

Rectifier Controller

Footprint

Various SKID solutions and layout available

Optional configuration

Busbar or cable configurations are available

Optional: Enhanced IP rating and corrosion protection for outdoor use

Available with top or bottom terminals for connection via busbar or cables

Optional: Liquid/liquid or liquid/air

Optional: Enclosure available

Various PWM controlled AC/DC rectifier configurations available

Various SKID solutions and layout available

Key benefits

Cost-effective customisation

Our modular PSU design ensures easy customisation and technical adaptation to match any green hydrogen plant size, operational range of electrolyzer, and grid requirements.

Compact footprint

We design your PSU to meet challenging layout requirements and provide containerised or skid-mounted options, lowering infrastructure costs and ensuring minimum installation effort.

Seamless grid integration

Utilising software models and simulating grid disturbances for steady-state and dynamic power performance, we work closely with you to anticipate grid compliance issues.

Flexible upscaling

Our modular approach provides scalability and flexibility for green hydrogen plants to start small and expand as demand grows, supporting projects from megawatt-scale to gigawatt-scale.

Bankable solutions

We deliver exceptional efficiency and reliability, allowing us to offer performance-based warranties that reduce technical and financial risks for developers and strengthen investor confidence.

Industrialisation experts

As the leading converter manufacturer in wind, we apply our global manufacturing scale and industrialisation expertise to deliver reliable, cost-effective Power Supply Units.

Customising to your specific requirements

Customised to balance plant-specific requirements, electrolyzer specifications, and grid requirements.

Our Power Supply Units meet diverse technical and operational needs: from output demands and complex layouts to electrolyzer operational ranges and compliance with TSO or regional grid requirements.

With a modular design approach, we offer full flexibility to configure indoor or outdoor installations and select the optimal components for your green hydrogen plant. Options include transformer types (dry or oil), AC connections (busbar or insulated cables), rectifiers, control systems, and cooling solutions

This flexible approach guarantees a Power Supply Unit fit for your plant’s technical and operational requirements.

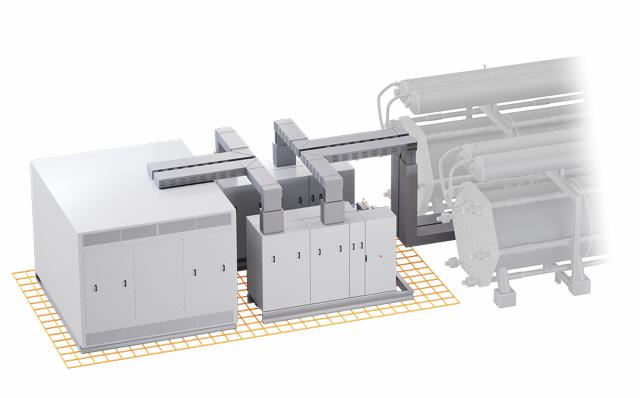

PSU design concepts

Designed for seamless site integration, our Power Supply Units accommodate even the most challenging indoor or outdoor layout requirements, including customised solutions for SKID-mounted installations.

Modularity as the backbone for customisation

Modular building blocks enable faster time-to-market and more cost-effective power supply solutions.

Our Power Supply Units use scalable, standardised components that can be combined and customised to meet plant-specific, electrolyzer, and grid requirements.

Designed for extensive pre-configuration, our Power Supply Units are pre-assembled and tested in controlled factory environments, eliminating the need for on-site functional and operational testing and accelerating time to operational readiness.

Offering exceptional flexibility, our modular design approach is ideal for industrial-scale green hydrogen production, supporting faster deployment and more reliable integration into large green hydrogen plants.

Case story:

Powering Sunfire’s 100 MW electrolyzer system

KK Wind Solutions will supply customised Power Supply Units for Sunfire’s 100 MW electrolysis plant, part of one of Europe’s largest green hydrogen projects in Germany.

Sunfire selected KK Wind Solutions for their ability to deliver tailored PSUs that convert electricity from the grid into stable, efficient power for the electrolyzers, meeting specific grid and plant requirements.

With production already underway, including testing and quality verification, this partnership sets the stage for future large-scale green hydrogen projects.

Rectifiers designed with high efficiency

Developed specifically for green hydrogen application, our rectifiers are customised to your electrolyzer’s operational range, and plant-specific output.

Case story:

3 MW PSUs for alkaline electrolyzers

Stiesdal Hydrogen launched its green hydrogen electrolyzer plant in Glansager, Denmark, with KK Wind Solutions supplying 3 MW power and control systems.

Stiesdal Hydrogen partnered with KK Wind Solutions to develop an end-to-end Power Supply Unit for an alkaline electrolyzer. The first system was delivered to a Power-to-Gas plant in Glansager, southern Denmark.

The plant converts surplus CO2 from the biogas process into additional biogas, using green hydrogen from the electrolyzer and a biological process.

KK Wind Solutions delivered multiple 3 MW Power Supply Units, control system hardware, and integrated software applications.

SERVICES & SUPPORT

Complete plant lifecycle support

We support PSUs throughout the entire plant lifecycle, from feasbility to operations, helping optimise performance and reduce the Levelised Cost of Hydrogen (LCOH).

Grid integration service

With expertise in grid compliance and integration simulation, we ensure seamless grid connection. Our PSUs are also designed for fast installation and easy servicing to minimise downtime risks.

Commissioning service

Our commissioning service includes a full documentation package, installation supervision, and PSU commissioning. Installation can also be provided on request for a seamless and efficient deployment.

Reliable spare parts

To ensure uninterrupted operations, we offer tailored spare parts packages that let you store critical components with us or receive them directly, enabling seamless replacements when needed.

Maintenance & support

Our maintenance services cover scheduled and unscheduled preventative maintenance, while our expert support ensures your PSU runs reliably, with rapid troubleshooting to keep operations seamless & efficient.

Discover our end-to-end Power Supply Units designed for green hydrogen production.

Connect with a specialist to explore customised Power Supply Units designed for your plant’s specific needs.